Outstanding accuracy

Offers outstanding accuracy for precise, reliable measurements.

Fast, detailed readings

Take detailed readings quickly and efficiently.

Precise assembly made easy

Makes it easy to accurately mount scanned elements, ensuring consistency across our 3D and 2D models.

Suitable for low-light environments

Can scan in low-light environments, providing sufficient visibility to capture quality data.

Seamless integration

Integrates seamlessly into your 3D and 2D design and engineering projects.

With the Scan Focus M70, we have a precise and efficient tool for carrying out detailed surveys and facilitating our projects.

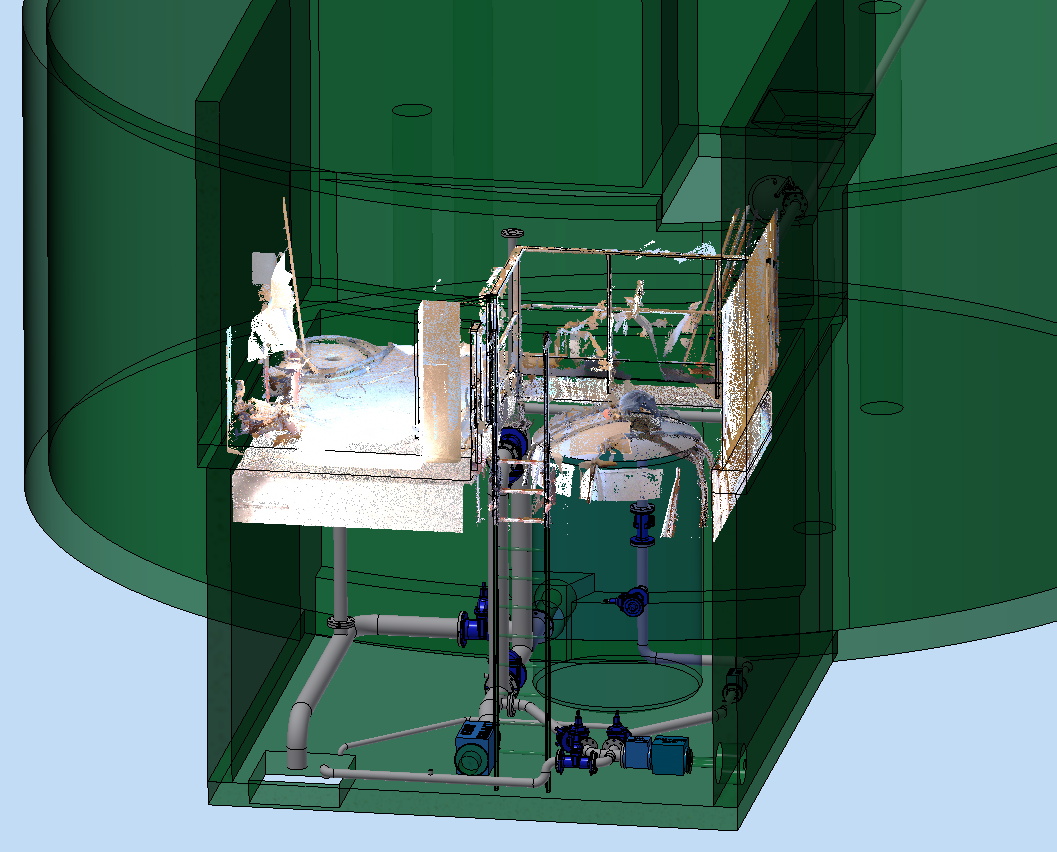

The 360° 3D Scan can be used to obtain a file following a point cloud to visualise the environment.

A point cloud is a set of 3D coordinates obtained from a 3D scan, accurately representing the surface of an object or scene. Used to create detailed digital models, it facilitates analysis and design in various industrial fields.

The advantages of Scan :

- Hard-to-reach areas (e.g. inside tanks, high structures, roofs)

- Passage of new piping through an existing aquifer

- Precise surveys of the environment (e.g. production lines, equipment, buildings, updating of factory plans for new installations)

- Record all geometries to design directly on the point cloud

- Simulation of machine handling, to define the specifications and the definition of the work (e.g. bringing a new machine into a workshop)

- Chain dismantling / replacement

How we use it

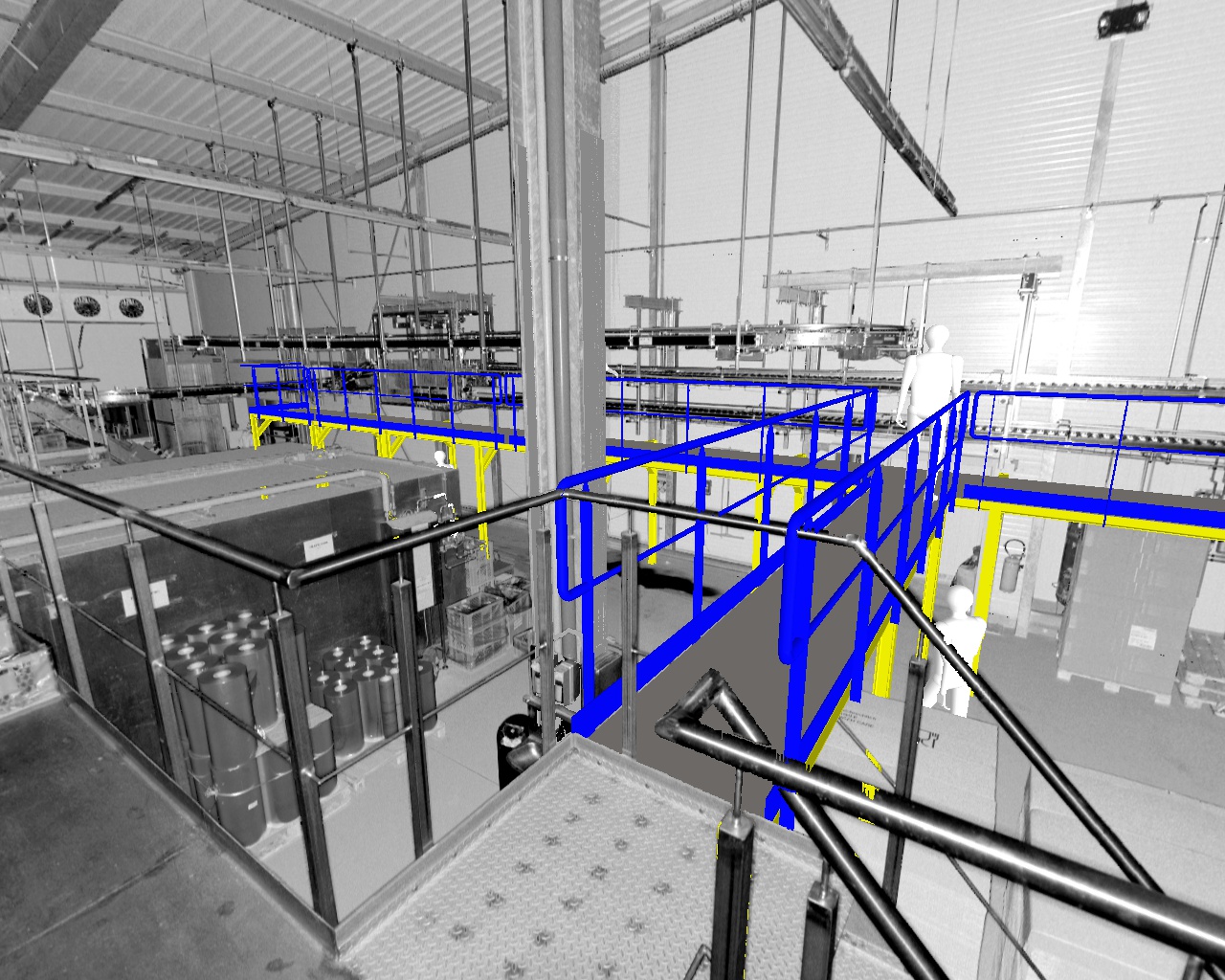

Line layout

We carry out precise surveys for line layout, ensuring accurate positioning of components.

Example: Isolation of existing machines, removal or integration of components on a point cloud, validation of positions.

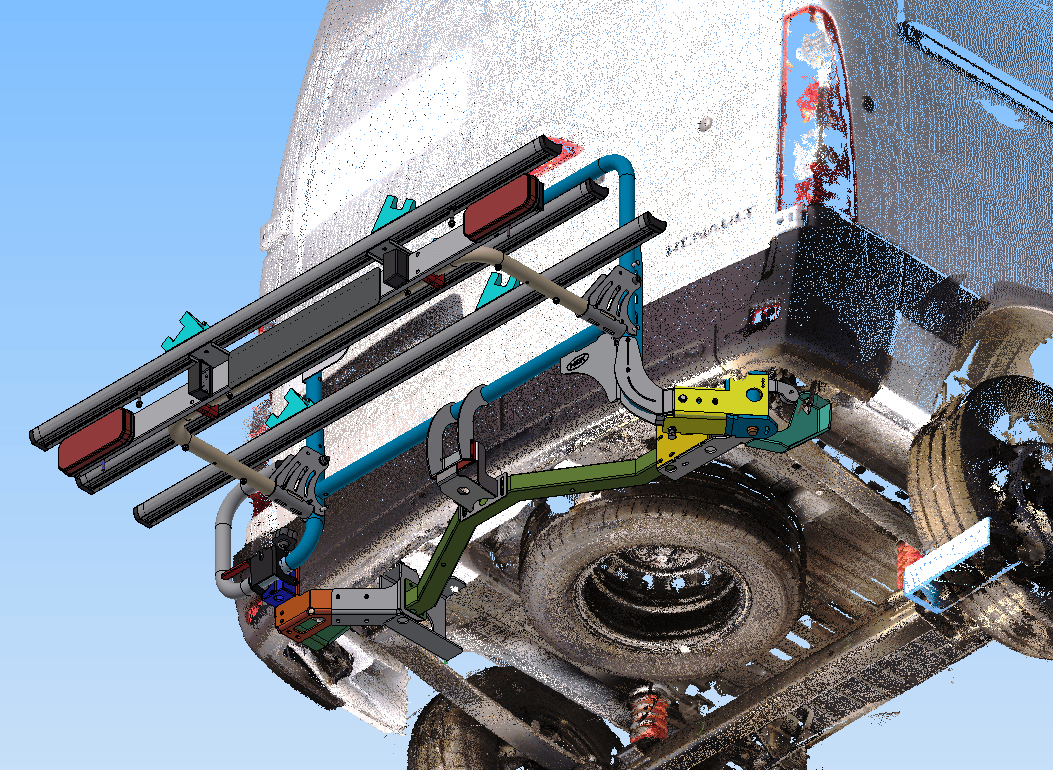

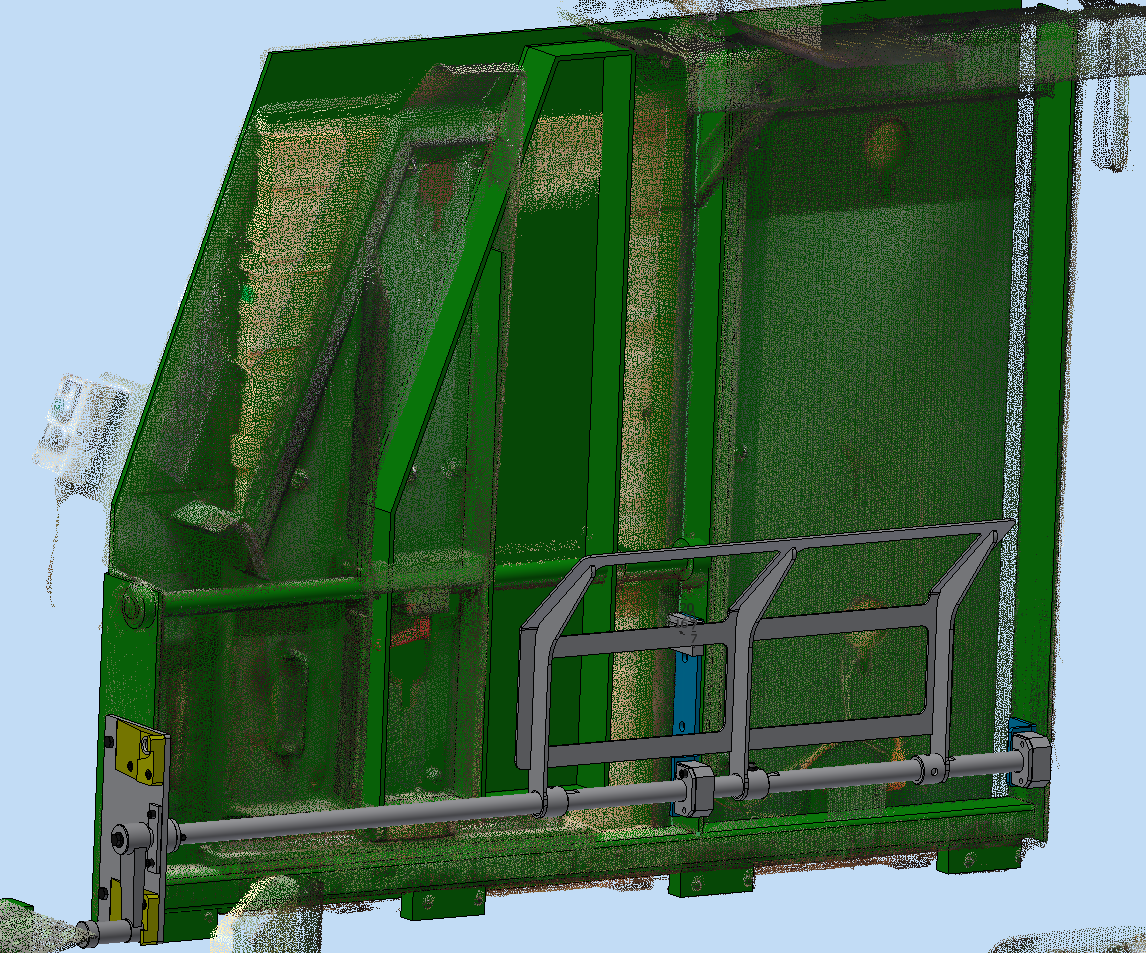

Structure and steelwork

Accurately studies metal structures such as walkways, staircases and indoor/outdoor access.

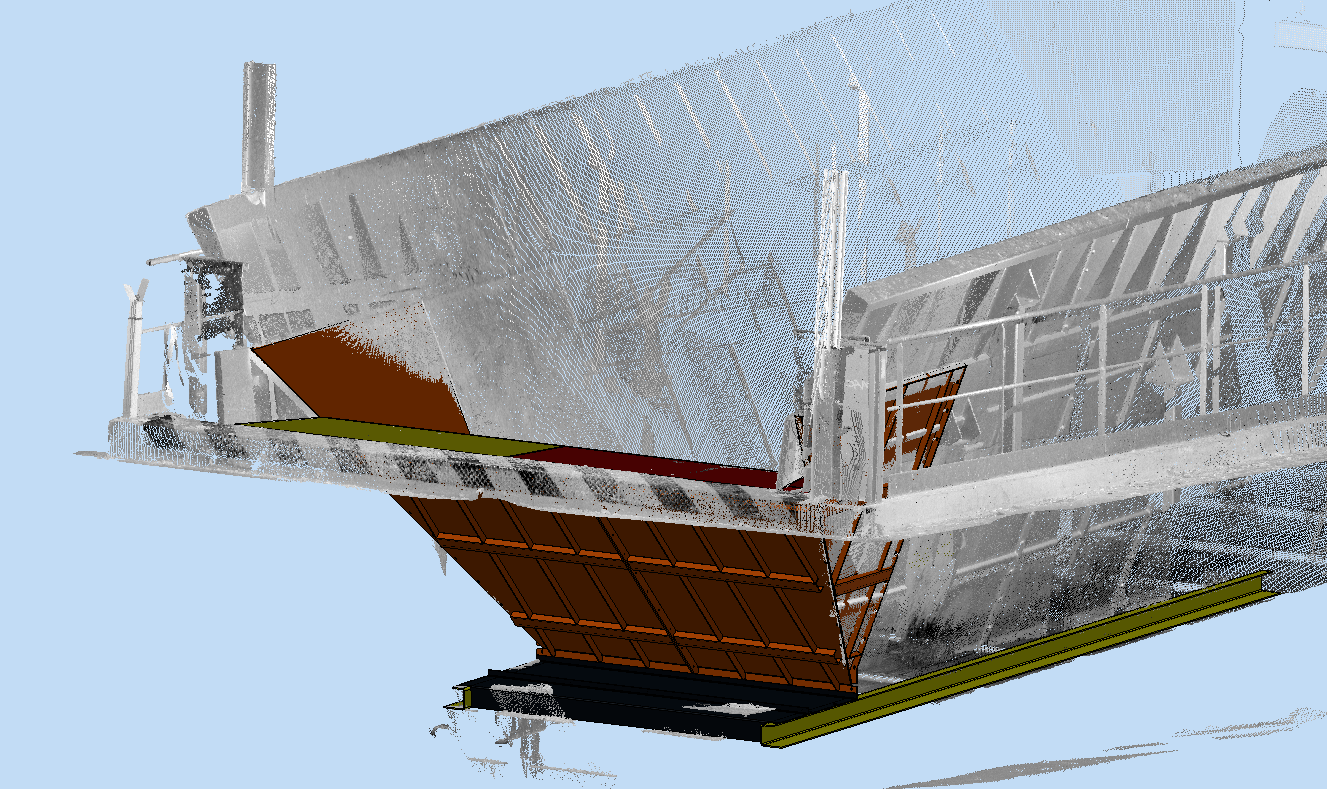

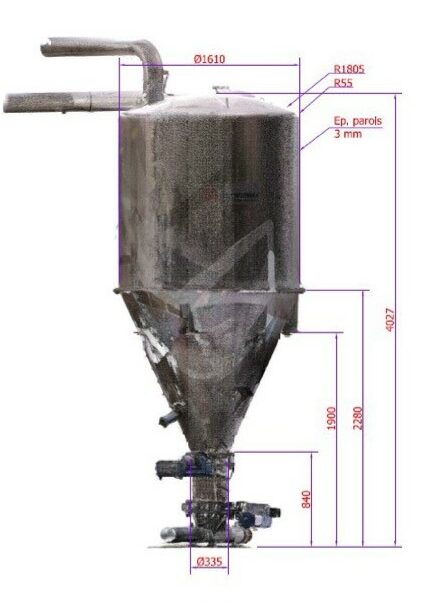

Boilermaking

Integrating metal structures into a specific environment. We can carry out calculations and draw up detailed manufacturing plans.

Example: Hopper

Measurement/Volumetry

We can carry out precise measurements for your factory plan updates and also make it easier to take measurements in hard-to-reach places.

Example: interior of a tank, height measurement